Call Us Now

08045476983

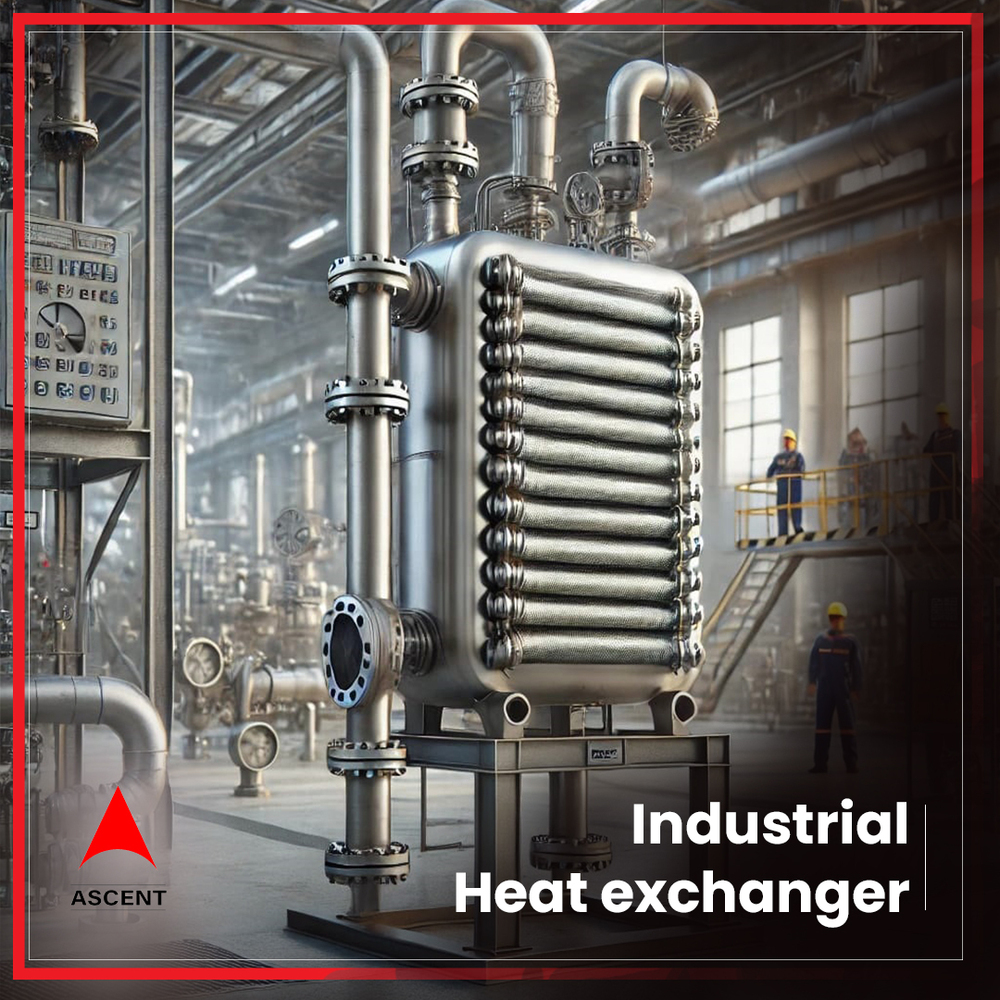

Industrial Steam Boilers for Roller Heating

Product Details:

- Voltage 220-440 Volt (v)

- Pressure Medium Pressure

- Fuel Type Other

- Condition New

- Style Vertical

- Usage Industrial

- Material Carbon Steel/Stainless Steel

- Click to view more

Industrial Steam Boilers for Roller Heating Price And Quantity

- 1 Unit

- 325000 INR/Unit

Industrial Steam Boilers for Roller Heating Product Specifications

- Industrial

- New

- Vertical

- Fully Automatic

- Carbon Steel/Stainless Steel

- Boiler Tube

- 220-440 Volt (v)

- Other

- Medium Pressure

- Industrial Steam Boilers

- Standard

Industrial Steam Boilers for Roller Heating Trade Information

- 10 Unit Per Month

- 3 Week

- As per requirement

- All India

- ISO 9001:2015 ,MSME - Udyog Aadhaar , ISO 9001:2015 - EEPC INDIA , IEC- Certificate

Product Description

Industrial steam boilers play a vital role in roller heating applications, providing a consistent and efficient heat source for industries like textiles, paper mills, rubber processing, and metal rolling. By delivering uniform and controlled steam, these boilers enhance production quality, reduce downtime, and improve energy efficiency.

Key Features & Benefits:

Precise Temperature Control Ensures stable and uniform heat distribution, preventing overheating and ensuring consistent product quality.

High Efficiency & Low Fuel Consumption Advanced combustion technology reduces fuel usage, lowering operational costs.

Multiple Fuel Options Compatible with coal, biomass, oil, gas, and electricity, providing flexibility based on industry needs.

Robust & Durable Construction Made from high-grade materials for long service life and low maintenance.

Automated Operation Features intelligent control systems for easy monitoring, efficient performance, and safety assurance.

Eco-Friendly & Low Emission Designed for clean and efficient combustion, meeting environmental regulations and reducing carbon footprint.

Versatile Capacity Options Available in various sizes to meet the specific steam demands of small, medium, and large-scale roller heating applications.

Investing in a reliable and efficient steam boiler ensures consistent roller heating, improved process control, and enhanced product quality. Whether used in textile mills, paper processing, or rubber manufacturing, a well-designed industrial steam boiler contributes to higher productivity and cost savings, making it an indispensable part of modern industrial heating solutions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Boiler' category

Shop No.2, 1st Floor, Nalanada Shopping Center,

Station Road, Goregaon (w), Mumbai 400062.

Works:

Process Equipment Division:

Plot No. J-188, Tarapur Ind. Est., Boisar,

Dist. Thane - 401506.

Boilers & Heating Systems Divison:

Bommasandra Industrial Area, Bangalore.

Cooling Towers Division:

Jai Bhawani Compound, Naik Pada, Vasai.

Dist. Thane

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese