Call Us Now

08045476983

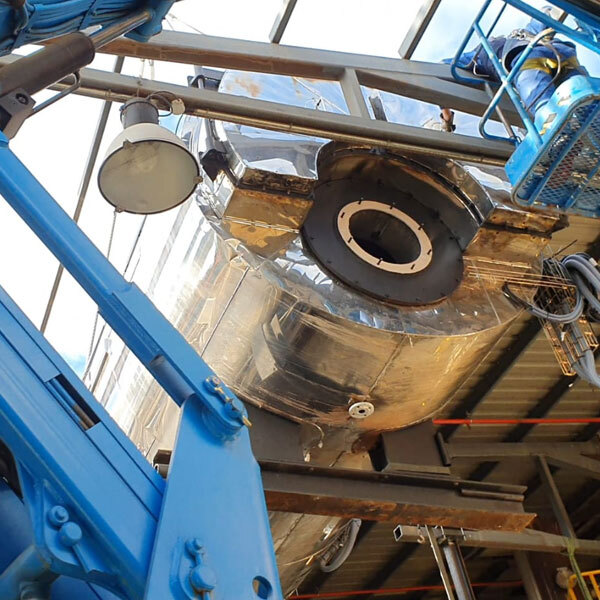

Industrial Steam Boiler for Power plants

Product Details:

- Fuel Type Coal- Fired

- Pressure Medium Pressure

- Style Horizontal

- Output Steam

- Condition New

- Usage industries

- Material MS, steel, carban

- Click to view more

Industrial Steam Boiler for Power plants Price And Quantity

- 200000.00 - 400000.00 INR/Unit

- 1 Unit

- 200000 INR/Unit

Industrial Steam Boiler for Power plants Product Specifications

- MS, steel, carban

- Steam

- industries

- Steam Boilers for Power Plants

- New

- Customizable

- Customizable

- Coal- Fired

- Horizontal

- Medium Pressure

Industrial Steam Boiler for Power plants Trade Information

- All India

- ISO 9001:2015 ,MSME - Udyog Aadhaar , ISO 9001:2015 - EEPC INDIA , IEC- Certificate

Product Description

Industrial steam boilers are the backbone of power plants, providing high-pressure steam to drive turbines for electricity generation. These boilers are designed to ensure maximum thermal efficiency, fuel savings, and consistent steam supply, making them essential for large-scale power generation.

Key Features & Benefits:

High Efficiency & Performance Advanced heat transfer technology ensures optimum fuel utilization, reducing energy wastage and enhancing overall plant efficiency.

Heavy-Duty Construction Manufactured using premium-grade steel and corrosion-resistant materials, ensuring long operational life even under extreme conditions.

Fuel Flexibility Can operate on coal, oil, natural gas, biomass, or waste heat, allowing power plants to choose the most economical fuel source.

Advanced Safety Mechanisms Equipped with pressure monitoring, emergency shutdown systems, and automated controls to prevent operational hazards.

Environmentally Friendly Designed to comply with global emission standards, reducing pollution and contributing to sustainable energy production.

Customizable Capacities Available in various capacities to suit small, medium, and large-scale power plants with different steam and power requirements.

Reliable & Continuous Steam Supply Ensures consistent energy production, minimizing downtime and improving overall power plant performance.

User-Friendly Operation & Low Maintenance Designed for easy maintenance and automated controls, reducing operational costs and ensuring smooth functionality.

By incorporating a high-performance industrial steam boiler, power plants can achieve greater efficiency, reduced fuel costs, and a more sustainable power supply. Investing in a modern steam boiler system helps ensure uninterrupted electricity generation, meeting the demands of industries, businesses, and households.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Boiler' category

Shop No.2, 1st Floor, Nalanada Shopping Center,

Station Road, Goregaon (w), Mumbai 400062.

Works:

Process Equipment Division:

Plot No. J-188, Tarapur Ind. Est., Boisar,

Dist. Thane - 401506.

Boilers & Heating Systems Divison:

Bommasandra Industrial Area, Bangalore.

Cooling Towers Division:

Jai Bhawani Compound, Naik Pada, Vasai.

Dist. Thane

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese