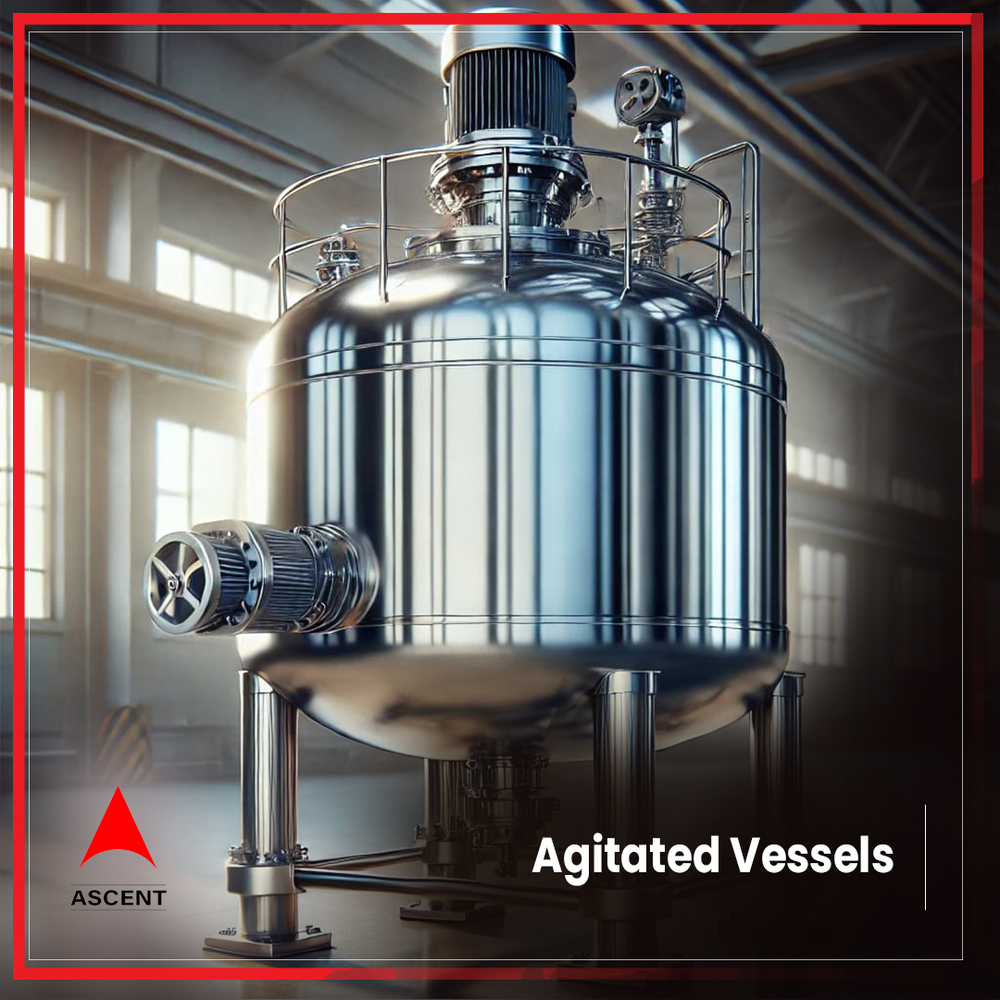

Process Reactors

Price 200000.00 INR/ Unit

Process Reactors Specification

- Phase

- Three Phase

- Material

- Stainless Steel

- Capacity

- 30 Ltr

- Surface Treatment

- Polishing

- Voltage

- 100 Watt (w)

- Feature

- High Performance

- Color

- Silver

- Warranty

- Yes

Process Reactors Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Day

- Delivery Time

- 1 Week

- Packaging Details

- As per requirement

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015 ,MSME - Udyog Aadhaar , ISO 9001:2015 - EEPC INDIA , IEC- Certificate

About Process Reactors

Process Reactors are essential industrial equipment used in chemical processing, pharmaceutical manufacturing, petrochemical industries, and other applications where controlled reactions take place. These reactors facilitate chemical transformations under specific temperature, pressure, and catalyst conditions, ensuring efficiency and precision in production processes.

Key Features:

High-Quality Construction Made from stainless steel, carbon steel, or specialized alloys to withstand extreme conditions.

Customizable Design Available in batch, continuous, or semi-batch configurations to suit different industrial needs.

Efficient Heat Transfer Integrated with heating or cooling jackets, coils, or external heat exchangers.

Pressure & Temperature Control Designed to operate at a wide range of pressures and temperatures for various chemical reactions.

Corrosion Resistance Special coatings and materials for handling aggressive chemicals.

Mixing & Agitation Options Equipped with mechanical agitators, baffles, or high-shear mixers for uniform reaction control.

Applications:

Chemical Processing: Synthesis of organic and inorganic compounds.

Pharmaceutical Industry: Drug formulation and API (Active Pharmaceutical Ingredients) production.

Petrochemical Sector: Crude oil refining, polymerization, and hydrocarbon processing.

Food & Beverage Industry: Fermentation and flavor enhancement.

Wastewater Treatment: Neutralization and detoxification of hazardous waste.

Process Reactors are vital in ensuring safe, controlled, and efficient chemical processing across industries. Designed to enhance productivity and minimize energy consumption, these reactors play a crucial role in industrial-scale productions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Process Equipment Category

GMP Reaction & Distillation Systems for Bulk Drugs and Active Pharmaceutical Ingredients

Price 100000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Voltage : 220240V

Material : Other

Warranty : 1 Year

Computerized : No

Venturi Scrubbers

Price 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110215 Volt (v)

Material : SS304, SS316, FRP

Warranty : 1 year

Computerized : No

Drum Flaker

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220440 Volt (v)

Material : Other, Stainless Steel

Warranty : Yes

Computerized : Yes

Industrial Dryer

Price 200000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 240 440 Volt (v)

Material : Steel Alloy

Warranty : Yes

Computerized : Yes

Shop No.2, 1st Floor, Nalanada Shopping Center,

Station Road, Goregaon (w), Mumbai 400062.

Works:

Process Equipment Division:

Plot No. J-188, Tarapur Ind. Est., Boisar,

Dist. Thane - 401506.

Boilers & Heating Systems Divison:

Bommasandra Industrial Area, Bangalore.

Cooling Towers Division:

Jai Bhawani Compound, Naik Pada, Vasai.

Dist. Thane

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese