Call Us Now

08045476983

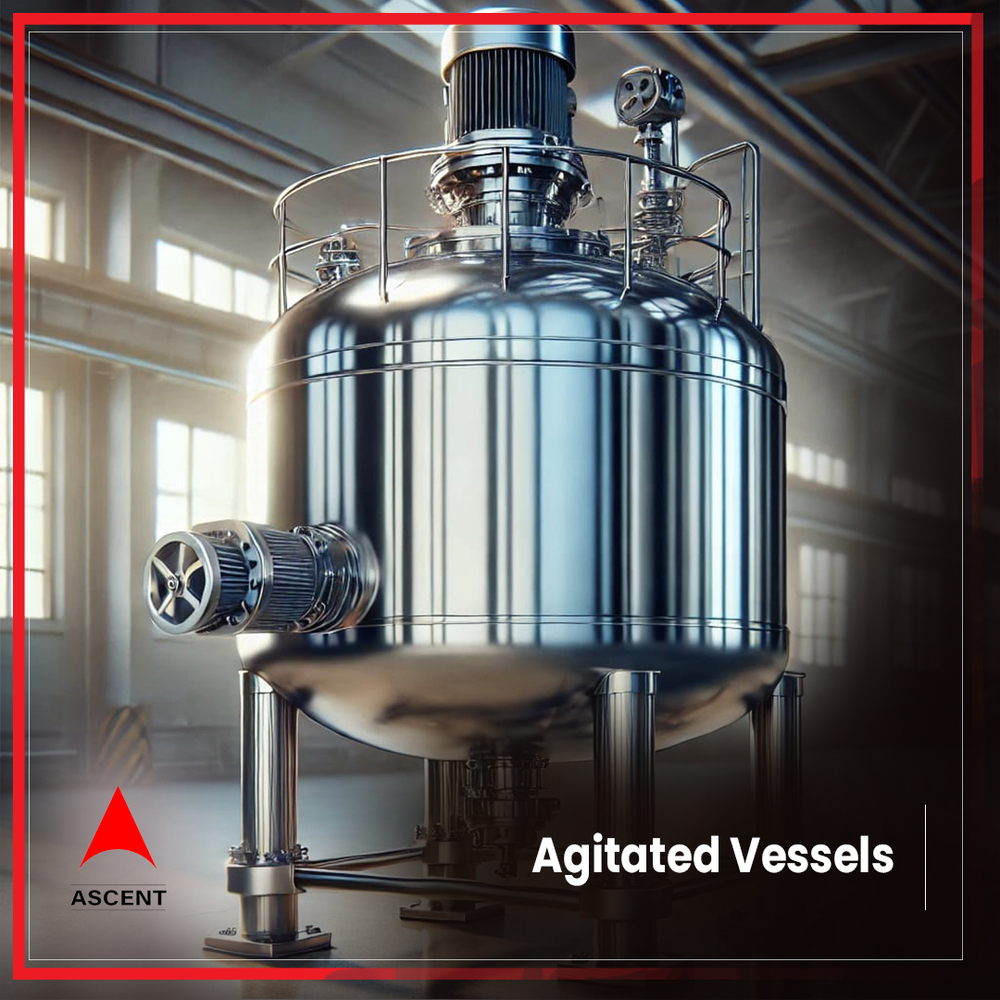

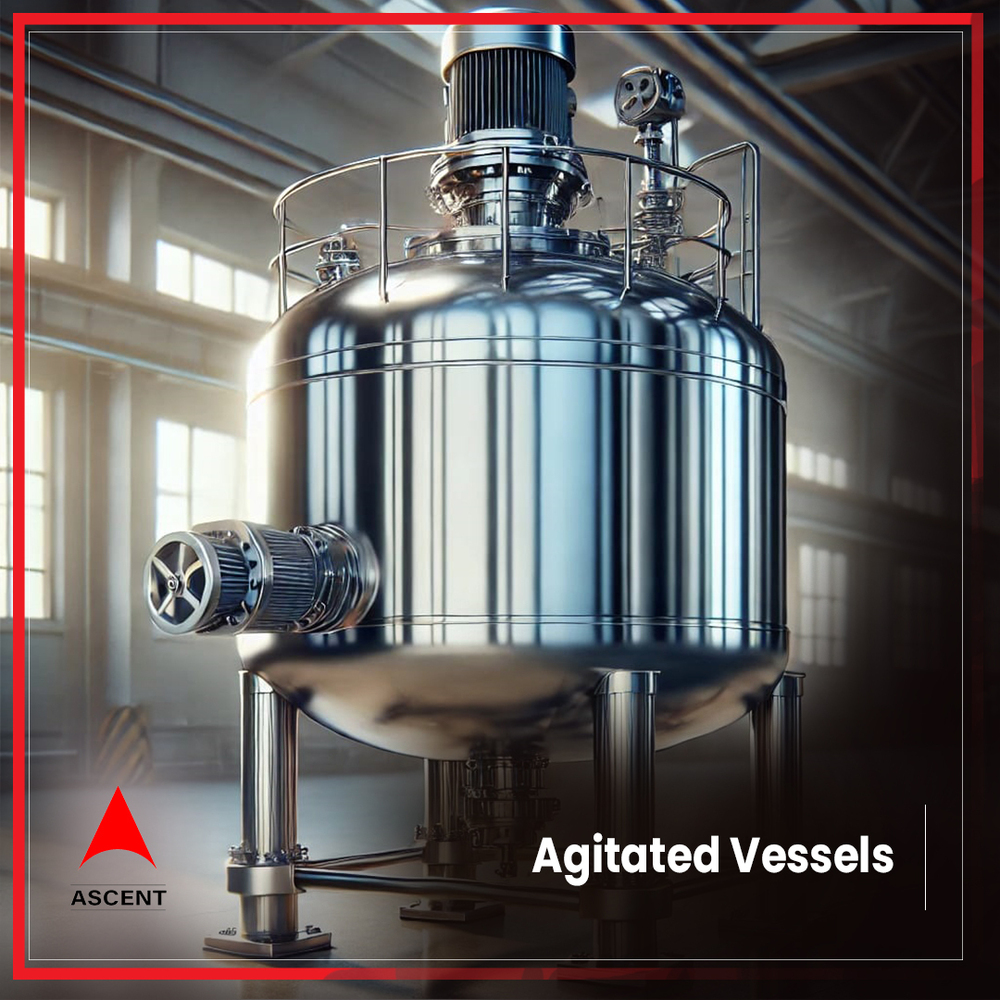

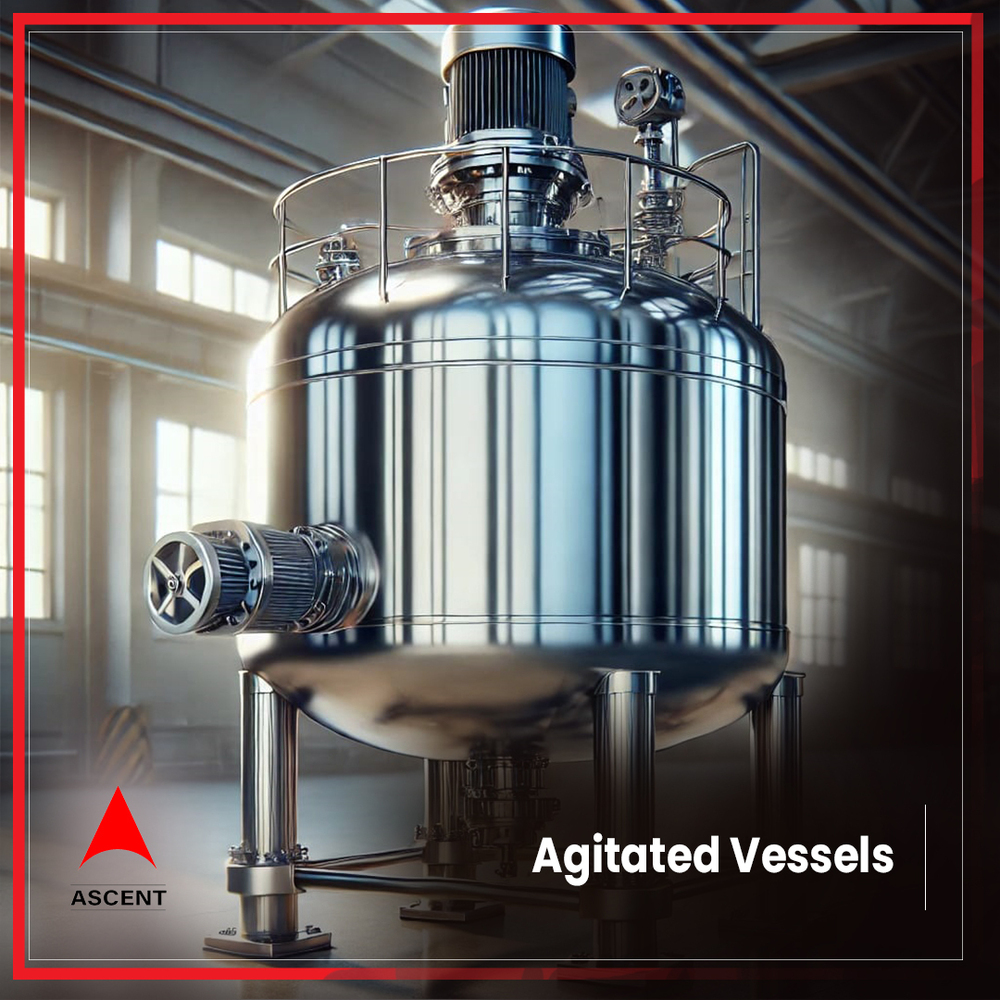

ASCENT MACHINERIES - Agitator

Product Details:

- Usage Industries

- Material MS

- Product Type Agitators

- Condition New

- Color Silver

- Click to view more

ASCENT MACHINERIES - Agitator Price And Quantity

- 1 Unit

ASCENT MACHINERIES - Agitator Product Specifications

- Agitators

- Silver

- Industries

- MS

- New

ASCENT MACHINERIES - Agitator Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 5 Unit Per Month

- 3 Week

- As per requirement

- All India

- ISO 9001:2015 ,MSME - Udyog Aadhaar , ISO 9001:2015 - EEPC INDIA , IEC- Certificate

Product Description

Industrial Agitators

At Ascent Machineries & Engineering Services, we manufacture and supply a wide range of high-performance Industrial Agitators designed for efficient mixing, blending, dispersion, and suspension of liquids and solids across diverse process industries. Engineered for durability and precision, our agitators are tailored to meet specific mixing requirements in sectors such as pharmaceuticals, chemicals, food & beverages, paints, cosmetics, and water treatment.

Types of Agitators We Offer

Top Entry Agitators

-

Ideal for large tank volumes and high-torque applications, used for mixing, blending, and maintaining product uniformity.

-

Side Entry Agitators

Used in large horizontal tanks where top entry is not practicalsuitable for oil, petrochemicals, and beverages. -

Bottom Entry Agitators

Designed for CIP (Clean-in-Place) and low-shear mixing, often used in hygienic applications like pharmaceuticals and dairy. -

Portable Agitators

Flexible and lightweight mixers for use in drums, containers, and smaller tankseasy to install and operate.

Key Features

-

High Mixing Efficiency Optimized impeller design for uniform mixing and reduced process time.

-

Custom Design Options Available in various shaft lengths, motor powers, and mounting styles.

-

Material Compatibility Constructed in SS304, SS316, Hastelloy, or customized as per process requirements.

-

Hygienic Construction For pharmaceutical and food-grade applications, with GMP-compliant finishes.

-

Seal & Bearing Options Mechanical seals, stuffing boxes, and bearing housings tailored to application needs.

-

Variable Speed Drive (VFD) Compatible Enables control over mixing speed and energy consumption.

Applications

-

Chemical Industry Mixing of solvents, acids, polymers, resins, and additives.

-

Pharmaceuticals Blending of active ingredients and formulations.

-

Food & Beverages Homogenization, flavor mixing, and ingredient dispersion.

-

Paints & Coatings Pigment dispersion and emulsion preparation.

-

Wastewater Treatment Aeration and chemical dosing.

-

Cosmetics & Personal Care Emulsification and homogenization of creams and gels.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in ' Industrial Storage Tank and vessels ' category

Shop No.2, 1st Floor, Nalanada Shopping Center,

Station Road, Goregaon (w), Mumbai 400062.

Works:

Process Equipment Division:

Plot No. J-188, Tarapur Ind. Est., Boisar,

Dist. Thane - 401506.

Boilers & Heating Systems Divison:

Bommasandra Industrial Area, Bangalore.

Cooling Towers Division:

Jai Bhawani Compound, Naik Pada, Vasai.

Dist. Thane

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese