Price 740000 आईएनआर/ Unit

Trade Information

- Minimum Order Quantity

- 1 Pole

- भुगतान की शर्तें

- , ,

- पैकेजिंग का विवरण

- As per requirement

- मुख्य घरेलू बाज़ार

- प्रमाणपत्र

- ISO 9001:2015 ,MSME - Udyog Aadhaar , ISO 9001:2015 - EEPC INDIA , IEC- प्रमाणपत्र

About

Hydrogenators / High Pressure Autoclaves

With or Without Gas Re-circulation Agitator

At Ascent Machineries & Engineering सेवाएं, we specialize in the design and manufacturing of Hydrogenators and High-Pressure Autoclaves for catalytic hydrogenation and other high-pressure chemical reactions. Engineered for precision and safety, these reactors are ideal for pharmaceutical, chemical, petrochemical, and research industries.

Whether with or without gas re-circulation agitators, our systems provide optimal mass transfer, efficient gas-liquid contact, and safe handling of pressurized gases under demanding reaction conditions.

Key Features

-

High Pressure & Temperature Capability

Designed to withstand working pressures up to 100 bar (customizable up to 300 bar) and temperatures up to 350°C. -

Optional Gas Re-circulation Agitator

Enhances mixing and gas distribution within the reactor for efficient hydrogenation. -

Precise Control System

PLC/SCADA based automation for real-time monitoring and process control. -

Superior Build Quality

Constructed with SS316 / SS316L / Hastelloy or other special alloys for corrosion resistance and long-term durability. -

Safety-First Design

Includes pressure relief valves, rupture discs, flame arrestors, and interlocks for secure operation. -

Efficient Heat Transfer

External or internal heating/cooling jackets for precise temperature regulation.

Applications

-

Pharmaceutical Industry – Hydrogenation of intermediates and APIs

-

Chemical Processing – Reactions involving gaseous reactants under high pressure

-

Dye & Pigment Manufacturing – High-pressure colorant synthesis

-

Food Additives – Hydrogenation in flavor and preservative processing

-

Research & Development – Pilot-scale testing of high-pressure reactions

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in प्रक्रिया रिएक्टर Category

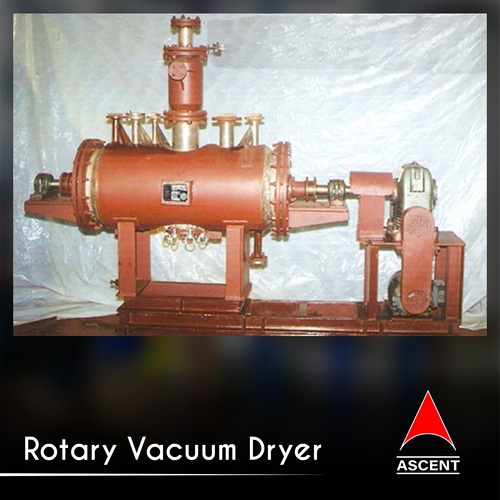

रोटरी वैक्यूम ड्रायर

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

वारंटी : Yes

वोल्टेज : वोल्ट (v)

ड्रम फ्लेकर

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

वारंटी : Yes

वोल्टेज : वोल्ट (v)

प्रोसेस रिएक्टर

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

वारंटी : Yes

वोल्टेज : वाट (w)

एनर्जी वेंटुरी स्क्रबर्स

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : यूनिट/यूनिट

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

वारंटी : 1 year

वोल्टेज : वोल्ट (v)

शॉप नंबर 2, पहली मंजिल, नालनाडा शॉपिंग सेंटर,

स्टेशन रोड, गोरेगांव (पश्चिम), मुंबई 400062।

वर्क्स: प्रोसेस इक्विपमेंट डिवीजन: प्लॉट नं.

जे-188, तारापुर इंडस्ट्रीज़ एस्ट., बोईसर, जिला.

ठाणे - 401506।

बॉयलर और हीटिंग सिस्टम डिवीजन:

बोम्मासांद्रा औद्योगिक क्षेत्र, बंगलौर।

कूलिंग टावर्स डिवीजन:

जय भवानी कंपाउंड, नाइक पाड़ा, वसई।

जिला। ठाणे

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें